Introduction

As the manufacturing industry advances, innovative automation factory models are transforming production processes. These models incorporate cutting-edge innovation, like computer based intelligence, mechanical technology, and IoT, to make more brilliant, more efficient processing plants that can satisfy the increasing need for excellent items. This content investigates the key components, advantages, and future patterns in automation factory models for current manufacturing.

Outline

Introduction

Key Components of Innovative Automation Factory Models

Advanced Mechanical technology

Computer based intelligence and Machine Learning Integration

IoT and Brilliant Industrial facilities

Secluded Design for Adaptability

Advantages of Automation Factory Models

Future Patterns in Automation Manufacturing

Conclusion

FAQs

Background: Key Components of Innovative Automation Factory Models

1. Advanced Mechanical technology

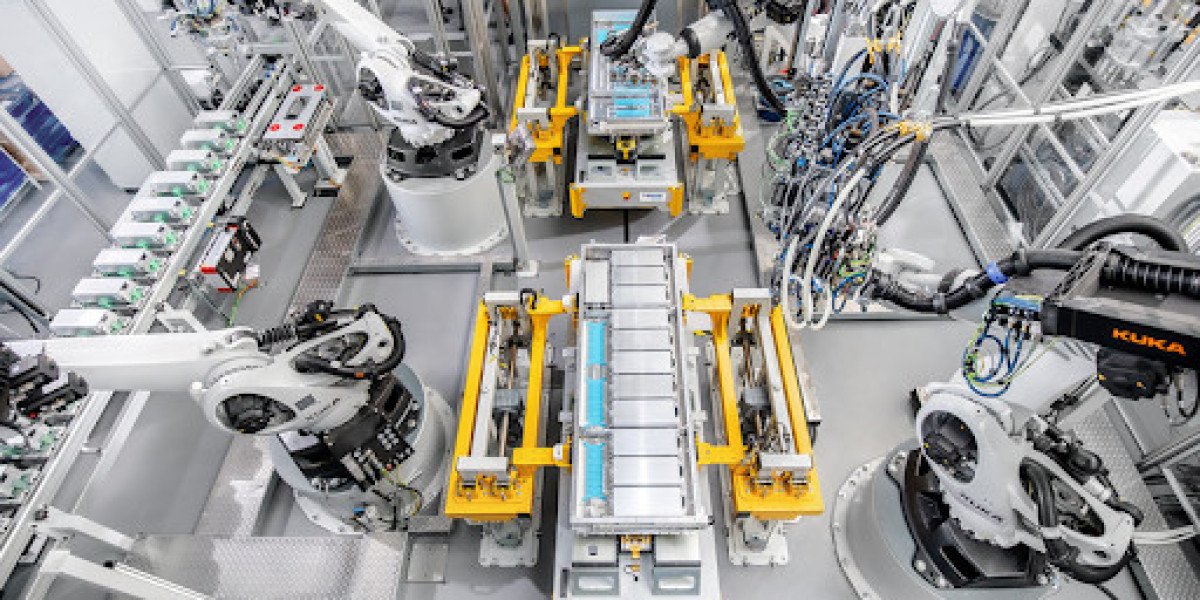

Robots are fundamental to automation, taking on errands that were once work intensive and redundant. These machines can handle undertakings with speed and accuracy, boosting efficiency while reducing blunders. Cooperative robots, or cobots, are increasingly being utilized to work close by humans, enhancing efficiency in complex cycles.

Why It Matters: Advanced mechanical technology further develops speed, exactness, and consistency in production lines.

2. Computer based intelligence and Machine Learning Integration

Man-made consciousness (computer based intelligence) and machine learning (ML) give the intelligence behind robotized direction. These innovations analyze information gathered from different pieces of the factory to enhance processes, foresee maintenance needs, and work on generally functional efficiency.

Why It Matters: simulated intelligence permits production lines to work on through constant insights and prescient analysis, reducing personal time and maximizing result continuously.

3. IoT and Shrewd Processing plants

The Internet of Things (IoT) empowers network between machines, sensors, and other factory systems, forming what is known as a shrewd factory. IoT systems screen ongoing information, allowing manufacturers to follow activities and immediately address issues. These interconnected systems likewise assist with optimizing energy use, manage inventories, and guarantee quality control.

Why It Matters: IoT increases perceivability into factory activities, leading to quicker issue goal and more efficient production management.

4. Secluded Design for Adaptability

A secluded factory design considers more straightforward reconfiguration of the production line to fulfill changing needs. As businesses develop or turn to new product offerings, particular systems give the adaptability expected to scale tasks or integrate new advances without exorbitant redesigns.

Why It Matters: Secluded design guarantees that plants can adjust rapidly to advertise patterns or changes in demand without disrupting production.

Advantages of Automation Factory Models

Increased Efficiency: Computerized systems work quicker and more reliably than manual work, leading to higher result significantly quicker.

Cost Efficiency: Automation diminishes work costs, minimizes squander, and enhances resource use.

Enhanced Item Quality: Automation systems produce uniform and exact items, resulting in better and less imperfections.

Further developed Adaptability: With particular and versatile designs, manufacturers can undoubtedly change production lines to oblige new items or market shifts.

Better Security: Computerized systems decrease the requirement for human laborers in dangerous conditions, lowering the gamble of mishaps.

Future Patterns in Automation Manufacturing

Increased Utilization of man-made intelligence and Independent Systems: simulated intelligence driven systems will continue to advance, offering more independent dynamic capacities, prescient maintenance, and machine learning-based upgrades.

Sustainability in Automation: Future models will zero in on energy efficiency and sustainability, incorporating green advancements to diminish the carbon footprint of manufacturing processes.

Advanced Twins: Virtual models of industrial facilities, known as computerized twins, will permit manufacturers to mimic cycles, test changes, and enhance production without disrupting real activities.

Conclusion

Innovative automation factory models are revolutionizing present day manufacturing, providing arrangements that increase efficiency, decrease costs, and further develop adaptability. As these innovations continue to create, the fate of manufacturing will turn out to be significantly more efficient, versatile, and intelligent. By integrating computer based intelligence, IoT, and advanced mechanical technology, manufacturers can assemble processing plants that are useful as well as receptive to the consistently changing business sector demands.

FAQs

What is a brilliant factory in automation?

A brilliant factory utilizes IoT, man-made intelligence, and associated systems to screen and enhance production processes progressively.

How do particular factory designs benefit manufacturers?

Secluded designs offer adaptability, allowing for speedy acclimations to production lines to fulfill shifting business sector needs.

Which job does man-made intelligence play in current manufacturing?

Simulated intelligence upgrades production, anticipate maintenance, and give information driven insights to continuous improvement.

How do automation factory models lessen costs?

Automation diminishes work and functional costs by increasing efficiency, minimizing waste, and optimizing resource use.

What are advanced twins in manufacturing?

Advanced twins are virtual models of actual plants, allowing manufacturers to mimic and test processes before implementing changes on the production floor.